Aluminum Coil With Wide Application

Specifications

|

Size (mm) |

Theoretical mass (kg/running m) |

|

1000 × 0.5 |

1.36 |

|

1250 × 0.5 |

1.69 |

|

1000 × 0.7 |

1.90 |

|

1250 × 0.7 |

2.37 |

|

1000 × 0.9 |

2.44 |

|

1250 × 0.9 |

3.05 |

|

1000 × 1.2 |

3.25 |

|

1250 × 1.2 |

4.04 |

Aluminum coils are used in a multitude of industries, including the automotive, building, electrical, food, pharmaceutical, and heat transfer industries. In many situations, aluminum is a material that is significantly superior to others. Standard mill finishes, brushed, checkered, color-coated, satin-finished, and anodized finishes are all available for aluminum coil.

Depending on the needs of the client, coils of aluminum foil or sheet can be cut.

All types of aluminum products and technological solutions are offered by the fully integrated manufacturer and supplier Fujian Xiangxin Co., Ltd. Aluminum plate, cast tooling aluminum plate, aluminum sheet (clad or bare), aluminum foil (clad or bare), aluminum strip (slit coil), aluminum circle, and aluminum coil are among the materials we are dedicated to becoming the top supplier of. Regarding Fujian Xiangxin aluminum coil, we provide aluminum foil and sheet coil in a wide range of alloys and thicknesses.

Typical Products of Aluminium Coil

3004 Aluminium Coil

5052 Aluminium Coil

6061 Aluminium Coil

1050 Aluminium Coil

1100 Aluminium Coil

3003 Aluminium Coil

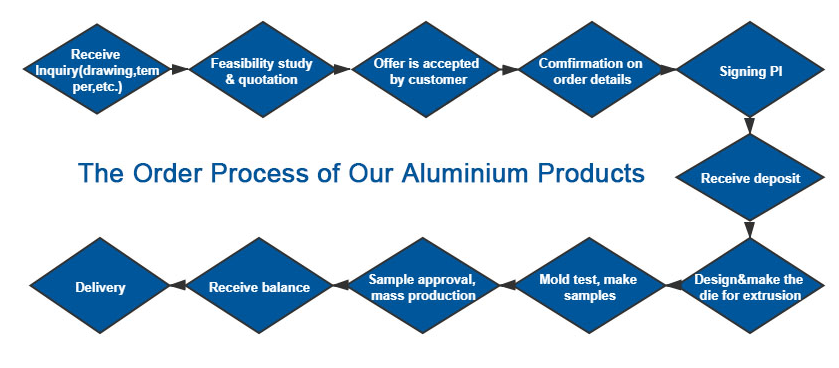

Order Process of Aluminium Coil

Specifications of Aluminium Coil

|

Products Name |

Aluminium Coil |

||

|

Alloy/Grade |

1050, 1060, 1070, 1100, 1200, 2024, 3003, 3104, 3105, 3005, 5052, 5754, 5083, 5251, 6061, 6063, 6082, 7075, 8011, 8079, 8021 |

||

|

Temper |

F, O, H |

MOQ |

5T for customized, 2T for stock |

|

Thickness |

0.014mm-20mm |

Packaging |

Wooden Pallet for Strip & Coil |

|

Width |

60mm-2650mm |

Delivery |

15-25days for production |

|

Material |

CC & DC route |

ID |

76/89/152/300/405/508/790/800mm |

|

Type |

Strip, Coil |

Origin |

China |

|

Standard |

GB/T, ASTM, EN |

Loading Port |

Any port of China, Shanghai & Ningbo & Qingdao |

|

Surface |

Mill Finish, Anodized, Color coated PE Film Available |

Delivery Methods |

1. By sea: Any port in China 2. By train: Chongqing(Yiwu) International Railway to Middle Asia-Europe |

Aluminium Alloy Grade

|

Alloy Series |

Typical Alloy |

Introduction |

|

1000 Series |

1050 1060 1070 1100 |

Industrial Pure Aluminium. In all series, 1000 series belongs to the series with the largest aluminum content. The purity can reach over 99.00%. |

|

2000 Series |

2024(2A12), LY12, LY11, 2A11, 2A14(LD10), 2017, 2A17 |

Aluminium-copper Alloys. 2000 series is characterized by high hardness, in which the content of copper is the highest, about 3-5%. |

|

3000 Series |

3A21, 3003, 3103, 3004, 3005, 3105 |

Aluminium-manganese Alloys. 3000 series aluminum sheet is mainly composed of manganese. The manganese content ranges from 1.0% to 1.5%. It is a series with a better rust-proof function. |

|

4000 Series |

4004, 4032, 4043, 4043A, 4047, 4047A |

Al-Si Alloys. Usually, the silicon content is between 4.5 and 6.0%. It belongs to building materials, mechanical parts, forging materials, welding materials, low melting point, and good corrosion resistance. |

|

5000 Series |

5052, 5083, 5754, 5005, 5086,5182 |

Al-Mg Alloys. 5000 series aluminium alloy belongs to the more commonly used alloy aluminum series, the main element is magnesium, the magnesium content is between 3-5%. The main characteristics are low density, high tensile strength and high elongation. |

|

6000 Series |

6063, 6061, 6060, 6351, 6070, 6181, 6082, 6A02 |

Aluminium Magnesium Silicon Alloys. The representative 6061 mainly contains magnesium and silicon, so it concentrates the advantages of 4000 series and 5000 Series. 6061 is a cold-treated aluminium forging product, which is suitable for applications requiring high corrosion resistance and oxidation resistance. |

|

7000 Series |

7075, 7A04, 7A09, 7A52, 7A05 |

Aluminium, Zinc, Magnesium and Copper Alloys. The representative 7075 mainly contains zinc. It is heat-treatable alloy, belongs to super-hard aluminium alloy, and has good wear resistance. 7075 aluminum plate is stress-relieved and will not deform or warp after processing. |

Features of Aluminium Coil

1. Good temperature resistance

Aluminum has a 660 degree melting point, which is not reached by the ambient temperature.

2. Excellent Corrosion resistance

It possesses strong adhesion, oxidation resistance, acid resistance, alkali resistance, corrosion resistance, decay resistance, and UV resistance because of the tight surface oxide film.

3. Color uniform, long-lasting, even and delicate

No matter how big the ceiling, its color and color are constant, long-lasting, and fresh because traditional spraying causes )

4. Rigid joint, extremely high strength of board

Combination of rigid and durable materials that is free to cut, slit, arc, balance, drill, fix the joints, and compress the edges.

5. Environmental protection

The roller paint contains active chemical molecules that encourage the production of a protective coating on the surface of the material, making it difficult to become yellow and compensating for the laminating board's flaws of quick discoloration. Active chemical molecules are reusable and stable, which satisfies environmental standards.

Applications of Aluminium Coil

Truck bodywork in the transportation sector, wrapped aluminum coil for heat transmission, and insulation material for the building sector are just a few examples of the many uses for aluminum coil.

● Further making utensils.

● Automobile application.

● Heat transfer (fin material, tube material).

● Solar reflective film.

● The appearance of the building.

● Interior decorating: ceilings, walls, etc.

● Furniture cabinets.

● Elevator decoration.

● Signs, nameplate, bags making.

● Decorated inside and outside the car.

● Household appliances: refrigerators, microwave ovens, audio equipment, etc.

● The consumer electronics: mobile phones, digital cameras, MP3, U disk, etc.

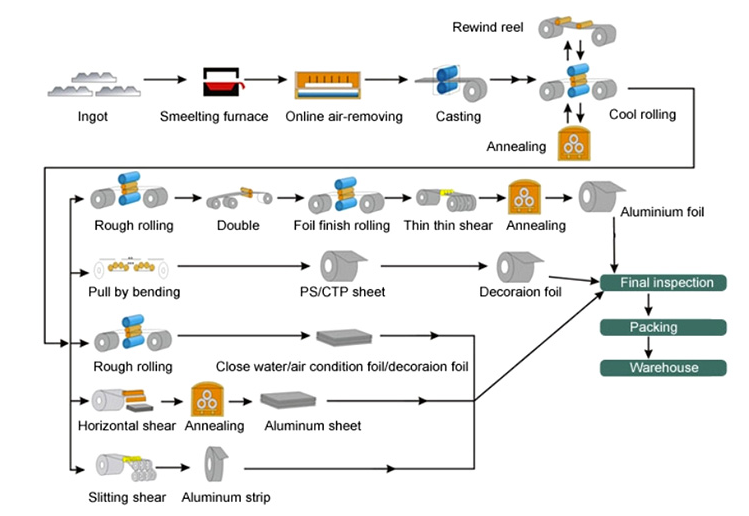

Processing of Aluminium Coil

Aluminium Ingot/Master Alloys — Melting Furnace — Holding Furnace — Slab — Hot Rolling — Cold Rolling — Slitting machine (vertical cutting to narrow width) — Annealing Furnace (unwinding) — Final Inspection — Packing — Delivery

How To Choose Aluminium Coil?

It is crucial to keep in mind that when selecting aluminum coil, the qualities and the particular application scenario directly influence the selection of the appropriate alloy. The flowing qualities of aluminum coil must be taken into consideration before purchase:

● Tensile Strength

● Thermal conductivity

● Weldability

● Formability

● Corrosion Resistance

Surface Coating For Aluminium Coil

1. Fluorocarbon coated color coated aluminium coil (PVDF)

The vinylidene fluoride homopolymer or a copolymer of vinylidene fluoride and additional trace amounts of the fluorine-containing vinyl monomer are the key components of the fluorocarbon coating, which is a PVDF resin coating. The fluoric acid base's chemical composition is combined by a fluorine/carbon link. The physical characteristics of fluorocarbon coatings are distinct from those of ordinary coatings due to their chemical structural stability and firmness. In terms of mechanical qualities, impact resistance is equally as strong as abrasion resistance and performs particularly well in adverse weather and environments, demonstrating enduring resistance to fading and UV. The molecular structure of the coating is tight and has great weather resistance once the high-temperature barbeque has been formed into a film. It is particularly appropriate for indoor, outdoor, and commercial decoration and presentation.

2. Polyester coated aluminum coil (PE)

The polyester coating created by repeatedly baking the surface of the aluminum plate can result in a solid layer that is adherent and has decorative and protective qualities. It has an ultraviolet protection layer. The monomer for the polyester resin is a polymer with an ester bond in the main chain, and an alkyd resin is then added. Depending on the gloss, the ultraviolet absorber can be separated into a matt and a high-gloss series. It has excellent gloss and smoothness, a better texture and hand feel, and may lend layering and three-dimensionality to colored aluminum items in addition to providing them with rich color. The coating can shield items from corrosive substances, temperature variations, wind, rain, snow, UV radiation, and other elements.

About Company

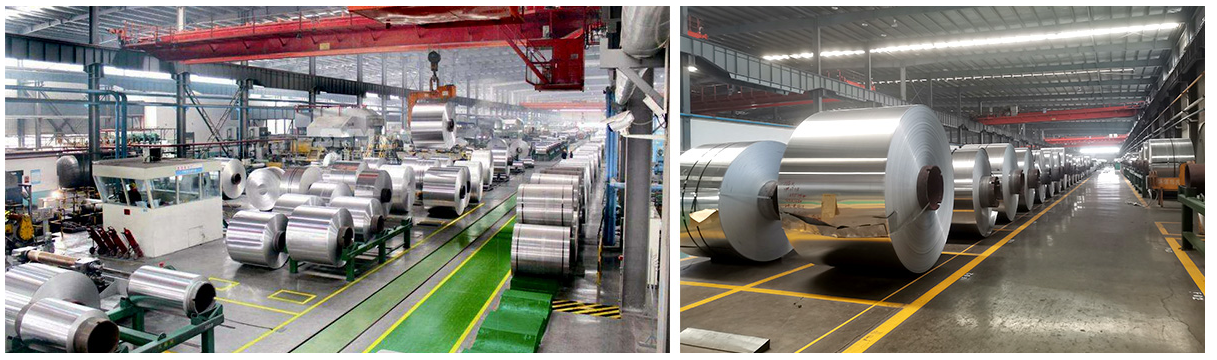

A fully integrated aluminum manufacturer, Fujian Xiangxin Corporation offers a wide range of aluminum products and technical solutions. Aluminum plate, aluminum sheet, aluminum strip, aluminum foil, aluminum circle, aluminum heat transfer material, aluminum profile, precision aluminum tube, aluminum machining parts, and aluminum stamping parts are among the materials we are dedicated to being the top provider of. One of China's largest producers of aluminum is Fujian Xiangxin Corporation. We offer a sizable facility, top-notch amenities, enough production capacity, and the widest selection of items. In five provinces, we have six manufacturing bases. Headquarters are in the aluminum industrial town of Qingkou, Fuzhou. We have five research and development centers, more than 4,000 employees—600 of whom work in research and development—more than 200 patents, an annual R&D budget of 220,000,000 RMB, and a 320,000 ton manufacturing capacity.

A melting-holding furnace, casting machine, pusher-type heating furnace, 1+1+3 hot rolling mill, 1+5 hot rolling mill, stretching machine, roller hearth quenching furnace, ageing furnace, 3-stand tandem cold rolling mill, 2-stand tandem cold rolling mill, and single stand cold rolling mill, intelligent high bay storage, tension leveling line, trimming line, and air-floating line are just a few examples of the advanced equipment that Fujian Xiangxin invests heavily in to ensure the quality.

Our Advantages

1.Pure primary ingot

2.Accurate dimensions and tolerance

3.Meet anodizing and deep drawing requirement

4.High-quality surface: the surface is free from defects, oil stains, waves, scratches, roll mark

5.High flatness

6.Tension-leveling, oil-washing

7.Mill finish/ETD lubricant surface

8.With decades of production experience

Supply Ability

2000/Tons Per Month

Packaging

Our goods are marked and packaged in accordance with laws and customer preferences. Every effort is made to prevent harm from occurring during storage or shipping. The typical export packing, which is coated with craft paper or plastic film. Products are delivered in wooden cases or on wooden pallets to prevent damage. For simple product identification and quality information, the outside of the packages are also marked with clear labels.

FAQ

Q: What’s the MOQ?

A: Generally, the trial order will be accepted. The MOQ can be confirmed according to the different products.

Q: Do you have OEM service?

A: Yes. A variety of product sizes, quality and quantities can be customized according to your need.

Q: Could you support a free sample?

A: Yes, we could offer the sample free of charge; you only need to pay the cost of freight.

Q: How about the delivery time?

A: Within 20-25 days after receiving the deposit.

Q: How about your payment terms?

A: 30%TT in advance and the balance against of copy of B/L.